2-Ethylhexyl Bromide: Development, Properties, Applications, and Future

Historical Development

Chemists branched into alkyl halide synthesis more than a century ago, always searching for molecules with broader uses. 2-Ethylhexyl bromide didn’t start off as anyone’s headline compound, but as plasticizers and specialty chemicals in the 20th century surged, more eyes turned its way. Manufacturers saw potential, thanks to its reactivity and the door it opened to larger chemistry. Demand kept growing, especially in the late 1900s as industries saw the unique value that alkyl bromides like this one deliver—sometimes in pharmaceuticals, sometimes in advanced coatings or specialty synthesis. Once easy access to raw materials united with new purity standards, it stopped being just a lab curiosity and became a workhorse for multiple sectors.

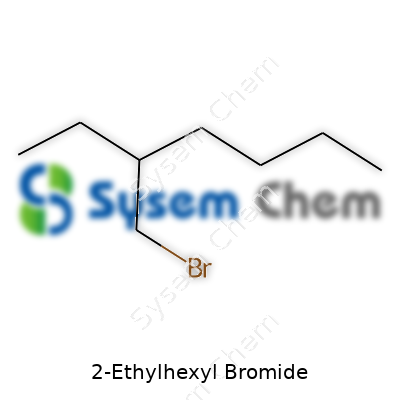

Product Overview

2-Ethylhexyl bromide often comes as a clear, colorless to pale yellow liquid. Its main uses range from organic synthesis to functioning as an intermediate in manufacturing certain pharmaceuticals and agrochemicals. People who work in plastics and rubber know it best as a tool for introducing bromine atoms into complex molecules. Because of its structure, 2-ethylhexyl bromide brings accessibility and versatility—many labs rely on it for alkylation reactions, passing that ethylhexyl group into new chemical architectures where a halide must react under gentle conditions. Strict packaging standards govern its containment, not just for purity but for safety during storage and handling.

Physical & Chemical Properties

This compound stands out because of its relatively high boiling point compared to lighter alkyl bromides, settling above 200°C. It weighs in at roughly 227.16 g/mol and offers low water solubility, keeping it focused on organic phases. Its refractive index sits moderately high, useful for purity checks in quality control. The density feels substantial to the hand, close to 1.14 g/cm³, which means it pours with a certain weight familiar to chemists who’ve handled similar liquids. With a molecular formula of C8H17Br, it delivers both the bulk of an 8-carbon chain and the reactivity that comes from bromide.

Technical Specifications & Labeling

Manufacturers must meet tight purity thresholds, often above 98%. Buyers expect full transparency in labeling—chemical abstracts registry numbers, hazard symbols, and detailed breakdowns of inert content. Storage recommendations specify protection from moisture and strong oxidizers, since even brief contact can start unwanted reactions. Every container tells you whether the compound’s intended for research or commercial use, following standards set globally to aid customs officers, hazard response teams, and the end-users in labs or plants. Extra requirements come into play in Europe, North America, and parts of Asia, as local chemical safety rules shape how 2-ethylhexyl bromide enters markets.

Preparation Method

Most producers synthesize 2-ethylhexyl bromide by reacting 2-ethylhexanol with hydrobromic acid or phosphorus tribromide. This pathway leans on classic substitution chemistry: swap the hydroxyl group for bromine under controlled, anhydrous conditions. The process scales well, as long as handlers monitor water content and temperature—too much heat or the wrong solvent can trigger competing reactions, dropping yields. On an industrial scale, continuous flow reactors and precise dosing raise efficiency while reducing byproduct formation, making it easier for chemists to access grams to tons of this molecule with consistent quality.

Chemical Reactions & Modifications

2-Ethylhexyl bromide plays a familiar role as an alkylating agent. The bromine leaves easily, especially in the presence of strong or mildly basic nucleophiles. In synthetic labs, it often upgrades simple molecules into more complex or lipophilic ones. Nucleophilic substitution, like the classic SN2 mechanism, is textbook here. Its bulky structure can sometimes add selectivity, letting chemists build up molecules step by step. Although less popular than the related chloride in some routes, the bromide’s higher leaving group ability keeps it relevant in many specialized reactions—especially where you want softer conditions and good conversions without heavy byproduct profiles.

Synonyms & Product Names

This compound often appears under several names: 1-bromo-2-ethylhexane, 2-ethylhexyl bromide, and sometimes just “Bromoethylhexane” in catalogues. Larger suppliers might brand it with abbreviated product codes, but small academic sources stick to systematic or trade names. Those who buy chemicals regularly keep CAS 18908-66-2 in mind to filter out mix-ups, since label confusion can spill trouble into both logistics and actual lab work.

Safety & Operational Standards

Strict safety rules stand between users and serious hazards. 2-Ethylhexyl bromide isn’t the worst actor among alkyl bromides, but its volatility and tendency to irritate eyes, skin, and the respiratory tract make full PPE — gloves, goggles, and chemical-resistant coats — essential. Inhalation brings acute symptoms, so well-ventilated fume hoods keep its use in check. Safety Data Sheets stress immediate washing for skin contact and quick disposal of contaminated tools to avoid long-term exposure. Safe storage calls for sealed glass or high-grade plastic, away from heat or reactive chemicals. These practices don’t just shield staff, but also prevent wider community impact if spills or leaks occur.

Application Area

Plasticizer and resin manufacturing heads the list, thanks to the compound’s ability to insert functional groups where others cannot. Chemical industries trust it to build intermediates for advanced lubricants, and its touch can be seen in sectors spanning from agriculture — where it sets up key pesticide scaffolds — to certain pharmaceutical syntheses. In research, it acts as a stepping stone for chiral ligands or other specialty chemicals, helping labs build libraries of analogs efficiently. Oil-field chemicals also use it in additive packages that must resist breakdown in harsh service.

Research & Development

Universities and corporate labs keep pushing to bring out new applications by adapting the reactivity of 2-ethylhexyl bromide to greener syntheses. Current research focuses on swapping out traditional, harsher reagents for bio-based alternatives and recycling byproducts within the plant. The molecule’s structure invites creative modifications — attaching unique side groups or chaining two or more pieces together for specialty surfactants. In pharmaceutical R&D, its use to construct longer side chains on active molecules aims for better absorption or new modes of action, adding more arrows to the chemist’s quiver. Improved analytical methods have dropped the detection threshold for impurities, driving researchers to retrace steps and tighten up every detail.

Toxicity Research

Toxicologists watch for chronic impacts beyond just irritation. Animal data show that high doses create liver and kidney stress, so responsible handling goes beyond accident prevention. Regular audits and monitoring in plants mean airborne concentrations rarely creep above safe levels, but the compound’s moderate volatility still urges care, especially around drains or work surfaces. Recent studies track potential environmental persistence and breakdown patterns, hoping to close gaps where past runoff or spills may have left traces in soils or waters. Waste handlers experiment with new treatments, aiming to minimize risks before this compound ever nears the environment at scale.

Future Prospects

Market analysts predict more use across emerging specialties — from nanoscale coatings to precision chemical delivery systems in agriculture. Innovations look to create analogs with adjusted reactivity, making synthesis cleaner or more selective. Moves to reduce waste and environmental emissions put pressure on manufacturers to update process technology while keeping the molecule’s core benefits at the fore. As more regions enforce tougher chemical controls, producers see incentives to design safer derivatives or recovery methods. Growth in advanced materials and new drug discovery could rely more on compounds like 2-ethylhexyl bromide as foundational building blocks. New synthetic routes, lower-impact reagents, better safety procedures, and stronger oversight should keep it relevant, bringing safer and more precise outcomes for both industry and society.

Chemical Building Block With Real-World Impact

2-Ethylhexyl bromide rarely grabs the spotlight, but its influence shows up in everyday products. This compound, featuring a bromine atom attached to an eight-carbon chain, often steps in as a starter for more complex molecules. Its use reaches across industries, especially where chemical synthesis drives innovation and production. My years of writing about chemicals for trade magazines have taught me that chemicals like this can be the quiet workhorses behind major technological advances.

Kickstarting Synthesis in Pharma and Agrochemicals

In pharmaceutical labs, researchers reach for 2-ethylhexyl bromide to create new drug molecules. The compound donates its carbon skeleton to synthesize active pharmaceutical ingredients. With bromine’s reactivity, it helps craft structures that fight disease or relieve pain. Agrochemical firms, tackling the world’s food needs, also tap into this compound. They build insecticides and herbicides that shield crops from pests and weeds. Experiences with farmers and agricultural chemists make it clear—innovation here matters. Without reliable intermediates, food yields slip and pests spread.

Creating Custom Surfactants and Specialty Chemicals

Modern manufacturing relies on surfactants—chemicals that change the way water interacts with oil or dirt. 2-Ethylhexyl bromide often acts as a base material for crafting these molecules. Through a few steps, the eight-carbon chain transforms into detergents and emulsifiers. Everyday items, like laundry soap or cleaners, rely on that chemistry. The push for safer, more effective cleaning agents means demand for high-purity, versatile starting materials keeps growing.

Polymer Additives for Plastics Revolution

Plastics shape most of our lives: toys, packaging, phone cases. 2-Ethylhexyl bromide helps make additives that adjust flexibility, color, or toughness in those plastics. As companies chase lighter packaging and less breakage, demand for specialty additives rises. During a site visit to a plastics factory in 2019, I watched first-hand as chemists blended such compounds to tweak the texture and strength of plastic parts rolling right off the line. Simple starting materials make these improvements possible.

Flame Retardants That Protect Homes and Devices

Fire safety specialists count on compounds derived from 2-ethylhexyl bromide. These derivatives slow down fires in furniture foam, wires, or building panels. It’s all about giving people more time to escape or about preventing small sparks from turning deadly. Having interviewed fire safety experts after the rash of building fires in the early 2000s, I realized the value of even small chemical tweaks. Each improvement saves lives, even if no one ever sees the actual chemical.

Taking Safety and Environmental Impact Seriously

Using substances like 2-ethylhexyl bromide brings up real questions. How does it affect workers? What are the long-term effects on rivers and soil? Regulations set limits, but thoughtful stewardship always sets the gold standard. Safer industrial practices and better waste management stand out as top priorities. Satellite projects in Germany and Japan have tried solvent recycling and airtight transport, strategies that actually work in cutting workplace and environmental exposure.

Looking for Better Alternatives

Green chemistry promises substitutes with fewer health risks and less environmental burden. Teams in research labs experiment with less hazardous alternatives, though progress sometimes moves slowly. Strong, transparent research and open industry standards make a difference. Every step toward safer, more sustainable industrial processes means a healthier world for everyone using the products this chemical helps create.

Understanding What You're Dealing With

Anyone dealing with 2-Ethylhexyl Bromide in a lab or industrial setting knows it’s not just another bottle on the shelf. The chemical smells strong, and touching it isn’t a good idea. Studies show that brominated organics like this one tend to irritate skin and eyes and often release vapors that sting both throat and nose. The Environmental Protection Agency lists compounds like these under hazardous materials for a reason. I’ve watched colleagues pay a heavy price for cutting corners — so using proper protection isn’t overkill, it’s just smart.

Gear Up: Personal Protection Makes All the Difference

I learned pretty fast that showing up with a pair of thin gloves hardly counts as being ready. Nitrile gloves, not latex, hold up against halogenated compounds. A pair of safety goggles blocks accidental splashes. I never skip on a lab coat and often use a full face shield when pouring or transferring. A fit-tested respirator rises on my list when work shifts into places with poor airflow, since volatile organics can sneak up through breath. Your clothes and shoes need to cover exposed skin, and keeping an extra set on hand can save a lot of hassle if the unexpected happens.

Ventilation: Out With the Fumes

Poor air circulation in the workspace will turn an annoying whiff into a real problem. I’ve always made sure that the room’s fume hood works, and if it’s down, I don’t handle volatile chemicals that day. Standard HVAC has never done enough for this type of job. Even opening a window won’t always keep up with what escapes during a spill or slow leak. Fume hoods have saved me and others from hours of headaches — both the literal and regulatory kind.

Storage: Safe and Separate

Mixing up storage is a recipe for trouble. I keep 2-Ethylhexyl Bromide locked up in purpose-built cabinets, away from heat, light, and anything that reacts with organics, especially oxidizers. Each container gets labeled with chemical name, date, and hazard class. We tape emergency contact numbers to the storage door and run spill drills twice a year. It sounds tedious, but it makes sense the day someone fumbles a bottle. I’ve seen improper stacking buckle a shelf and trigger a cascading spill. Just a few minutes of care each week takes care of most risks before they grow out of hand.

Spill Response: Fast and Focused

Most minor spills get controlled before they take down a shift. The best practice has always been to clear the area, contain with absorbent pads, and scoop into a sealed waste bag. We keep neutralizing agents next to the main workspace and train every new hire to use them. Scrubbing with soap and copious water works if skin contact happens, but it helps to know the nearest eyewash or shower station and keep it uncluttered. Reporting spills fast keeps people honest about mistakes and cuts down on hush-hush cleanup efforts that only hide trouble.

Training and Vigilance: Knowledge Saves Trouble

People new to these chemicals sometimes treat the safety data sheet like just another handout. It becomes more valuable when put into plain practice — details matter more than slogans around the lab. Regular briefings and honest stories let everyone know the real dangers. Safer labs grow from culture, not just rulebooks. Everyone who works with or near 2-Ethylhexyl Bromide should walk through emergency plans and wear their PPE without reminders. This teamwork approach doesn’t just prevent injuries; it stops the worst mistakes before they start.

Diving into 2-Ethylhexyl Bromide

Chemistry often sounds distant to most folks, but the formula and properties of compounds always connect back to the real world. 2-Ethylhexyl bromide offers a good example. The chemical formula for this material is C8H17Br. Its molecular weight lands at 193.13 g/mol — straightforward numbers with big implications.

The Building Blocks and Why They Matter

The backbone of 2-Ethylhexyl bromide consists of eight carbon atoms, seventeen hydrogen atoms, and a single bromine atom. That means you’re dealing with a molecule where a bromine atom attaches to a branched hydrocarbon chain. The nature of that structure sets it apart from simpler alkyl bromides, which you see all the time as laboratory reagents or intermediates in manufacturing.

Structure drives behavior. With this one, the branched chain disrupts packing when the substance turns to solid, so it generally stays as a colorless liquid at room temperature. That sounds like a small detail, but it can change how chemists use it in reactions, and how industries handle, store, or transport it. Anyone who’s spilled a little on their bench will remember the persistent smell and slightly oily feel.

Use Beyond the Beaker

For anyone who has worked with organic reactions, 2-ethylhexyl bromide pops up as a handy alkylating agent. Companies working in pharma and specialty chemicals rely on it whenever they need to tack on an ethylhexyl group to a molecule — something that can tweak solubility, boost bioavailability, or fine-tune the way a finished compound behaves. Even if you’re not in the lab, you use products every day that might start with reactions involving reagents like this.

Industrial-scale handling points to something bigger. The molecular weight of 193.13 g/mol puts 2-ethylhexyl bromide within easy reach for bulk synthesis without the volatility or fire risk linked to lighter organics like ethyl bromide. Companies value that kind of stability. Less chance of an unexpected fire, more confidence across the supply chain. Still, you end up needing solid engineering controls, since that bromine atom brings hazards if it escapes as vapor, leading to occupational health risks.

Factoring in Safety and Responsibility

Risk goes beyond just chemical burns or inhalation issues; environmental impact comes into play. 2-Ethylhexyl bromide, like most alkyl halides, doesn’t break down quickly in groundwater. Keeping it contained and disposed of properly stands out as a must. Having worked with similar compounds, I’ve seen the difference between sites that respect proper fume hoods and PPE versus those that cut corners — and the resulting problems always catch up, whether it's skin rashes today or regulatory fines tomorrow.

Companies can make improvements. Closed systems, scrubbers for vent lines, and real training about chemical handling cut down on accidents and environmental release. On the supply side, improved tracking through batch identification makes sure the product’s not just meeting regulatory expectations but also performing as expected for the customer every time.

The Takeaway: Details in the Data

Knowing the formula C8H17Br and molecular weight 193.13 g/mol isn’t just a trivia answer. It opens the door to understanding purpose, risks, and the best way to handle 2-ethylhexyl bromide in any setting. Precision in these basics lays the groundwork for safety, performance, and sustainable practice.

The Real Stakes of Chemical Storage

Storing chemicals seems like a trivial matter to outsiders, but those of us working with substances like 2-Ethylhexyl Bromide know there’s little room for error. This liquid carries a sharp, sometimes unmissable odor, and its reactivity reminds chemists and warehouse workers alike to show respect. Mishandling can lead to leaking drums, ruined labs, and health problems that stick around longer than anyone would like.

Putting Safety First

Most workers learn quickly to check the MSDS before handling chemicals, but busy days make shortcuts tempting. Storing this compound the right way keeps people breathing easy and operations running smoothly. Talking from my time in the backrooms of a specialty chemicals distributor, I’ve seen what goes wrong when someone overlooks storage rules for a bromide compound. Even a small spill can turn a workday on its head.

Keep 2-Ethylhexyl Bromide in air-tight glass or high-density polyethylene containers. Avoid using plain steel; the bromide reacts, especially in the presence of moisture. Large drums need seals checked regularly, especially if storage lasts more than a month. A couple of cracked gaskets or a slipped seal might not cause problems right away, but within weeks, you’ll smell contamination.

Cool, Dry, and Out of Sunlight

Heat and ultraviolet light speed up decomposition. Don’t stack this chemical next to windows or heat sources. Store it in a cool, shaded spot, far from any flame, boiler, or bright sunlight. The temperature sweet spot hovers around 15-25°C. In Texas summers, storage rooms creep above that, and problems start to multiply. Vapors build up and can eat through rubber or plastic caps, leading to leaks and those hazmat drills nobody enjoys.

A dry environment matters too. Bromides have a habit of drawing in moisture, setting up corrosion and increasing volatility. Humidity seeps in through cracks, so keep rooms well-ventilated and use desiccants in storage cabinets if your region is muggy. A cheap humidity gauge near storage shelves helps spot trouble before it gets expensive.

Segregation and Labeling: More than Bureaucracy

I’ve lost count of how many times companies store incompatible chemicals together to save shelf space. 2-Ethylhexyl Bromide does not belong next to strong oxidizers, acids, or bases. A wrong move can set off nasty smoke, and even small amounts of mixing contaminate valuable stock. Label everything clearly—no exceptions. I’ve seen new hires mistake one clear liquid for another and only realize after the reaction starts. Good labels save headaches and hospital visits.

Emergency Preparedness: Lessons Learned the Hard Way

Leaks and spills aren’t just possible—they’re nearly inevitable over a long enough timeline. Spill kits should sit within arm’s reach in any storage room. Training sessions feel repetitive, but skipping them invites trouble. I remember a minor leak where someone reacted by running water over a spill, spreading it instead of containing. Absorbent materials and ventilated rooms let everyone move on safely. Immediate access to PPE—goggles, gloves, and respirators—can turn a near-miss into a non-event.

Building Better Habits

Taking these precautions might seem like overkill until the day something goes sideways. Responsible storage habits grow from seeing the consequences of cutting corners. A safe shop earns trust from regulators, employees, and neighbors, all while avoiding drama, lost inventory, and costly downtime. For 2-Ethylhexyl Bromide, a few simple rules can make all the difference.

The Substance at a Glance

2-Ethylhexyl Bromide pops up in chemical manufacturing and some laboratory settings. This clear, oily liquid has a faint, almost sweet odor, but don’t let that fool you: its effects on health can be anything but subtle. I’ve spent years around chemicals like these, so I take workplace safety and personal protection seriously every day in the lab.

Immediate Health Hazards

Contact with 2-Ethylhexyl Bromide poses a few direct threats. Touching it can cause skin irritation—think redness and itching that sticks around long after you’ve washed your hands. If you breathe its vapors, you could feel dizzy or lightheaded. I've seen co-workers get headaches and throat irritation just by working too close to an open container. Those symptoms may seem minor, but over time, a steady buildup of exposure can put lungs and skin under constant stress.

Impact on Internal Organs

This chemical doesn’t just irritate. Swallowing it, even accidentally, can lead to nausea, vomiting, and abdominal pain. American Industrial Hygiene Association research notes that inhalation can affect the central nervous system, sometimes causing symptoms like confusion or drowsiness. Because 2-Ethylhexyl Bromide is a brominated agent, the liver has to work overtime to break it down, and repeated exposure puts people at risk for liver dysfunction down the line. In rare but serious situations, high levels of contact may also impact the kidneys, which filter waste from the blood.

Long-Term Concerns

No one wants to think about cancer risk in the workplace, but I know from personal experience that vigilance matters. Detailed animal studies have linked similar brominated compounds to an increased risk of tumors, especially with chronic exposure. Regulatory bodies like the Environmental Protection Agency urge employers to limit worker contact and to use strict controls for this reason. If you work somewhere that handles this substance, proper containment and protective gear should be non-negotiable expectations.

Protecting Health in the Workplace

Ventilation becomes crucial in any space using 2-Ethylhexyl Bromide. I’m a big believer in local exhaust systems—the kind that capture vapors right at the source and keep them from drifting across a countertop. Gloves and goggles do more than look official; they make the difference between a clean bill of health and a trip to the clinic. If you ever spill some, follow emergency procedures right away. Having quick access to a safety shower or eye wash station can prevent a bad accident from getting worse.

Room for Safer Practices

Workplaces need routine air quality checks, regular health screenings, and clear rules about chemical storage. I always make sure new staff know the risks from day one, since awareness is the first defense. Digital Material Safety Data Sheets (MSDS) should stay updated and available with practical emergency numbers posted close by. For companies, investing in training and modern protective equipment pays off by keeping team members safe and healthy over their careers.

Potential Solutions on the Horizon

Substituting less hazardous chemicals for 2-Ethylhexyl Bromide makes sense if it’s possible. Process engineers, chemists, and safety personnel can work together to review safer alternatives. If direct replacement isn’t an option, strict automation—handling materials inside sealed systems—can greatly reduce the chance for exposure. Regulatory oversight and industry self-audits push everyone to aim higher, so fewer workers face preventable health risks. Personal vigilance and strong policies can help make sure 2-Ethylhexyl Bromide remains a managed risk, not a hidden threat.